Chemical Industry

We offer a wide range of equipment for the chemical industry. We design, engineer and provide reliable systems regarding filling, mixing, diluting and handling of highly corrosive chemicals such as acid and lye. Our systems are compact and fully automatic with an exceptional level of precision, accuracy, safety and reliability.

Filling equipment for drums and containers

CF4-2S

Container Filler CF4-2S is a fully automatic filler designed to fill corrosive liquids into containers.

CF4-2S, suited for a range of containers (2-25 liters) has been developed for the chemical industry. The machine is designed for highly corrosive liquids and is designed to be connected to a ventilation system for evacuating toxic fumes. The filler performs a leak-test of the containers before filling, the filling is performed on a scale-unit for an exact filling.

The machine is made exclusively of acid-proof materials, stainless steel and plastic.

The filling machine can be connected to Källström Capping-machine to create a production line of both filling and capping.

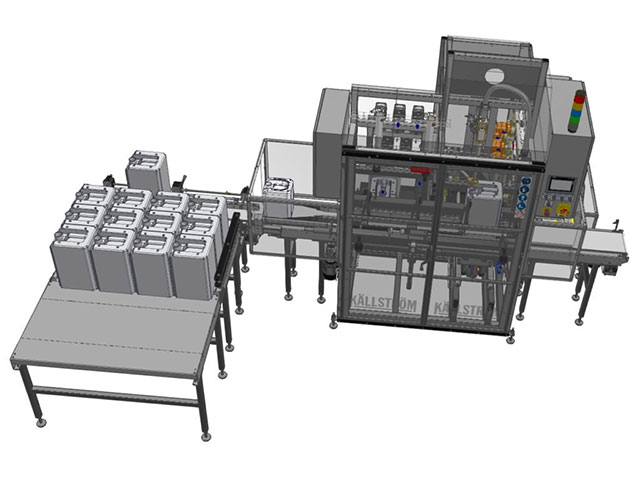

CF12

Container Filler CF12 is designed to fill corrosive liquids into containers (20–60 litres) placed on a pallet.

The pallet can be filled in two layers, for example, with 2 x 12 20-litre containers. The machine consists of a stand with a filling block centred in the stand. The filling block consists of 12 filling pipes, each with a valve. The filling volume is controlled by sensors for each container. The set volume is controlled via the HMI on the electric cabinet. CF12 can be fitted with built-in pallet scales, coriolis massflow sensor or electromagnetic flowsensor.

The machine is made exclusively of acid-proof materials, stainless steel and plastic.

The filling machine can be connected to several external tanks.

Capping machines for drums and containers

Capping Machine CM4-1S

CM4-1S has been developed for the chemical industry. The machine is designed to work together with a filler and is directly connected after the filling machine for putting caps on drums and containers making it possible to have filling and capping in one line.

CM4-1S is a fully automatic capping machine designed to work with containers filled with highly corrosive liquids and are designed to be connected to a ventilation system for evacuating toxic fumes.

The machine is made exclusively of acid-proof materials, stainless steel and plastic, which makes it entirely resilient against corrosive environment and corrosive liquids, like all Källström machines.

Scope of supply

In addition to our filling and mixing-equipment we offer:

Storage tanks

We supply a wide range of storage tanks for acid and other kind of chemicals.

Our storage tanks can be fitted with a range of different option equipment. Contact us for closer information, advice and suggestions.

Typical features

• Storage Tanks in PE and PP

• 500 – 50 000 l

• High safety and long working life

• Indoors or outdoors use

SED-3 Sedimentation Unit

The SED-3 Sedimentation unit is designed for automatic filtering of reclaim acid. Contaminates in the acid, like led particles, accumulates in a slurry tank and are also trapped in a filter unit on the machine.

The SED-3 Sedimentation unit is fully automatic and filters reclaim acid continuously through its lamella tank, and contaminates deposits in a slurry tank and a filter unit.

Led particles in the reclaim acid sinks to the bottom of the lamella tank and accumulates in the slurry tank as the acid slowly flows through the sedimentation unit. The smallest particles in the reclaim acid are filtered and collected in the filter unit of the machine. Slurry is evacuated via a diaphragm pump to external storage for further depositing and recycling.

Mixing & Diluting

We offer a wide range of mixing equipment.

Our goal is to provide highest quality equipment with outstanding performance and great flexibility that is easy-to-use and provides the highest accuracy in your production.

Accessories

We offer a wide range of acessories such as pumps, valves and sensor equipment regarding filling, mixing and handling of highly corrosive chemicals.

We manufacture and use parts with an exceptional level of precision and accuracy for safety and reliability.