Battery Industry

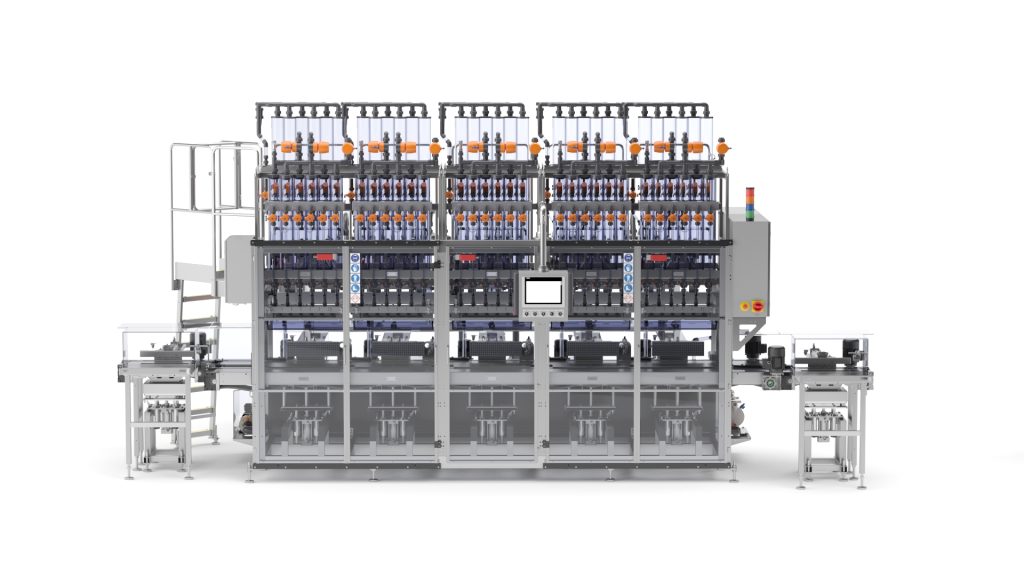

Filling equipment

We design and manufacture a wide range of filling solutions for all kinds of lead-acid batteries. We also provide corresponding systems for NiCd and NiMH batteries. Our systems are often tailor-made and custom-built to customer needs, and of course we provide counsel and advice for suitable solutions after need.

Our goal is to provide highest quality equipment with outstanding performance and great flexibility that is easy to operate.

Mixing & Dilution equipment

We design and produce dilution- and mixing-systems for different capacities and acid densities. We build systems suitable both for batch and continuous operation.

All our systems are compact and fully automatic with the highest level of reliability and safety.

Additional scope of supply

In addition to our filling and mixing-equipment we offer:

SK4-1S - Acid level control

The SK4-1 series is a fully automatic Acid Level Control equipment for flooded batteries, it has the same frame, structure and base construction as our acid fillers. SK4-1 uses fiberoptic sensors and offers an excellent accuracy with optical control of the battery cells filling level.

The SK4-1S is a single station control unit that performs an automatic control and makes sure the batteries are correctly filled and can also be fitted with an OCV-test. When fitted with an OCV-unit it performs an automatic battery voltage measurement as well. The control machine includes a reject unit with a reject arm and reject table, batteries that is not within parameters are pushed out on the reject table.

SED-3 Sedimentation Unit

The SED-3 Sedimentation unit is designed for automatic filtering of reclaim acid. Contaminates in the acid, like led particles, accumulates in a slurry tank and are also trapped in a filter unit on the machine.

The SED-3 Sedimentation unit is fully automatic and filters reclaim acid continuously through its lamella tank, and contaminates deposits in a slurry tank and a filter unit.

Led particles in the reclaim acid sinks to the bottom of the lamella tank and accumulates in the slurry tank as the acid slowly flows through the sedimentation unit. The smallest particles in the reclaim acid are filtered and collected in the filter unit of the machine. Slurry is evacuated via a diaphragm pump to external storage for further depositing and recycling.

Storage tanks

We supply a wide range of storage tanks for acid and other kind of chemicals.

Our storage tanks can be fitted with a range of different option equipment. Contact us for closer information, advice and suggestions.

Typical features

• Storage Tanks in PE and PP

• 500 – 50 000 l

• High safety and long working life

• Indoors or outdoors use

Trolley Filler

The Trolley Filler is a small mobile unit with it’s components mounted on a small carriage, with two turning wheels for easy handling.

The trolley is mainly designed for topping up flooded 2V batteries/cells. The filler contains a 70 liter tank, an electrical cabinet and a handheld manually operated filling nozzle with a simple adjustment for leveling. The Trolley can be used in production, garage or laboratory environment. It has a battery for it’s own on-board power source and can be used for both initial filling and for top-up leveling.