Filling

We design a wide range of battery filling-machines. Our goal is to provide highest quality equipment with outstanding performance and great flexibility that is easy-to-use and provides the highest accuracy in your production.

SLI-batteries

SLI is an acronym for Starting, Lighting, and Ignition; these processes are all consuming energy that is supplied by a vehicle’s battery. SLI is a lead-acid and rechargeable type of battery that is mainly used in automobiles and different vehicles.

Volumetric or level filling

We offer machines filling with a specific volume or to a specific level in each cell. The machine can be used for initial filling or for filling after formation.

Small. Medium. Large. Larger!

The acid fillers come in different sizes from one up to six filling heads in a single machine with capacity up to 25 batteries/minute. Future expansion plans? No problem. Our machines can be designed to handle retrofitting extra stations later on. The perfect way to grow as your production does.

Features

- Filling of SLI batteries

- Volumetric or level filling

- Up to six filling heads

- Capacity up to 25 batteries/minute

Options

Our machines can be fitted with a number of options. One common option is the battery reject station used for rejecting incorrectly filled batteries in the finishing line.

Automatic height adjustment of the filling heads will decrease change over time and reduce the risk for incorrect adjustment. If you want to fill with different acid densities this can be arranged with a tank designed to handle up to three different densities.

According to customer need our fillers can handle any voltage of batteries/battery cells between 2 and 36 volts.

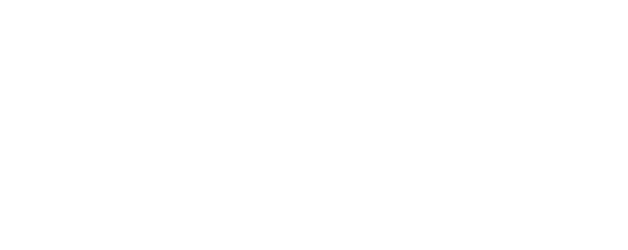

Filling equipment for flooded (SLI) batteries

SF4-2 - Level filling

SF4-2Q - Four filling stations

The SF4-2 family is designed for level filling. The machines are fully automatic filling machines available with different numbers of filling stations, with adjustable and automatic leveling of the filling heads designed for filling and acid leveling of SLI batteries. The filling process is pressure-aided and the leveling process is vacuum-aided. The SF4-2 is suitable both for initial filling before formation, and to be used on a finishing line after formation.

The SF4-2Q features four individual filling stations, typical suitable for initial filling before formation, but can just as well be used on a finishing line after formation.

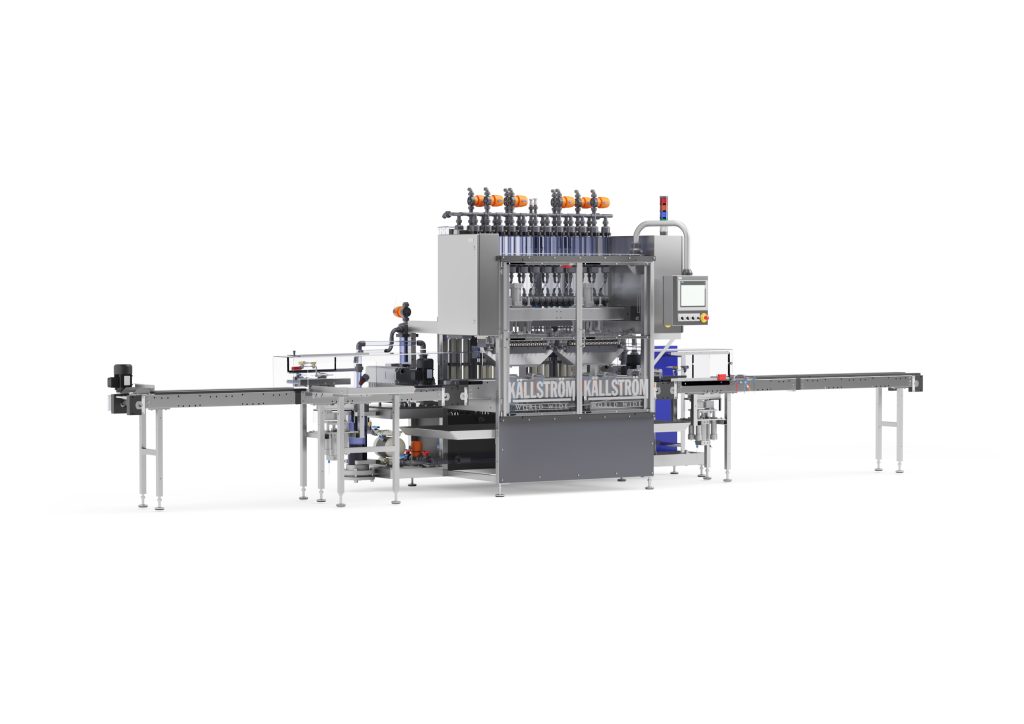

SF4-2D + SK4-1S - Two filling stations

The SK4 Acid Level Control is a stand-alone unit that can be combined with all our SF4-2 machines. The SK4-1S is a single station control unit that performs a control and makes sure the batteries are correctly filled and can also be fitted with an OCV-test.

The SF4-2D + SK4-1S in the picture features a two station filling machine and is outfitted with an single station Acid Level Control unit (SK4-1S), an optional feature on the SK4 is an OCV-test (Open Circuit Voltage), all typical suitable for a finishing line. The SF4-2 is also used for initial filling before formation.

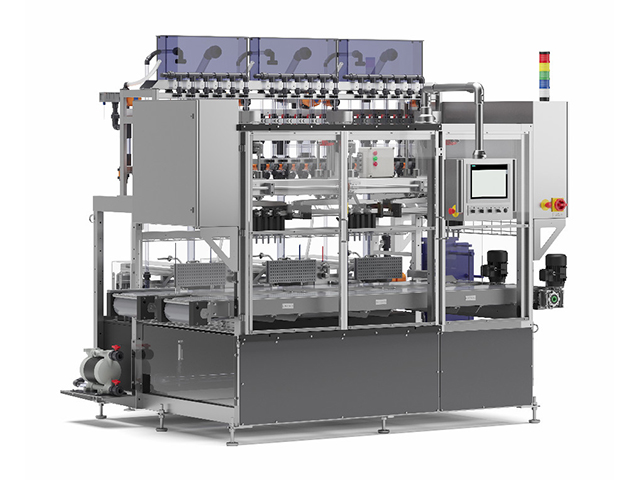

SF4-21 - Volumetric filling

SF4-21T - Three filling stations

The SF4-21 family is designed for volumetric filling. The machines are fully automatic filling machines available with different numbers of filling stations, with adjustable and automatic leveling of the filling heads.

The SF4-21T is a triple machine and consequently contains three individual filling stations, and contains double conveyors for more efficient production – one in-going and one out-going conveyor together with a cross-feed system makes the transportation within the filling machine very effective.

The machine in the picture is equipped with options: a heat exchange unit for cooling of the acid and a tank draining unit, containing a diaphragm pump for ready and convenient tank evacuation.

VRLA-batteries

VRLA – Stands for Valve Regulated Lead Acid and includes Gel and AGM. Typical characteristics are: maintenance-free, leak-proof, position insensitive. Batteries of this kind have a safety vent to release gas in case of excessive internal pressure build up. Mainly use is emergency lighting, RV, marine equipment, power backups and for electric or hybrid vehicles.

Accuracy Matters

We understand the importance of getting the right saturation in the plates. At the very core of the machine sits a state-of-the-art flow meter making sure to deliver acid just right for each specific battery.

The Coriolis flow meter is perfect for this job. Not only will it offer the best dosage accuracy but also provide read-out of Density and Temperature of the solution.

Under Pressure

Our machines offer great flexibility to manage the most complex fill procedures. Offering freedom to define unique sets of parameters such as vacuum level, fill- and soak times.

Manage up to ten steps per fill cycle in order to minimize dry-spots. Parameters are stored in recipes and can be accessed at any time from the machine’s HMI.

Features

- Fills a wide range of batteries from Motorcycle, Small Enginges Batteries to Standby batteries. Filling of 2, 6, 8, 12 and 24 Volt batteries.

- Four batteries/min

- Fill accuracy ±3 g/cell

Options

Our machines can be fitted with a number of options. First we have the Scales which will keep track on the Battery weights throughout the process. Together with Barcode/Matrix readers and an SQL-database they make a powerful combination.

If temperature controlled Acid is desired we also have the option to fit a heat exchanger onto the machine. The machines are able to handle several minus degrees Celsius.

For those who require even higher controlled process one can add the Individual Cell Vacuum monitor system. It can provide useful diagnostics on what’s happening within each cell during filling.

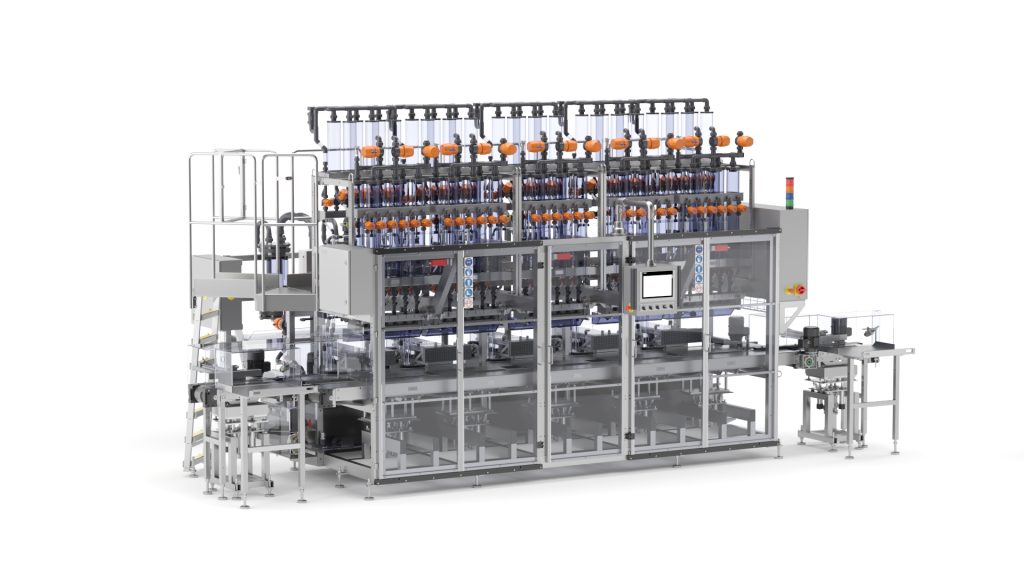

Filling equipment for VRLA batteries

SF4-8 - For monoblock batteries

AGM - Five filling stations

The SF4-8P is a machine with five filling stations. This machine can be designed for filling cold acid, chilled down to – 20o C, and the acid is measured with an extremely accurate Coriolis mass flow meter.

The machine in the picture has options fitted: two scale units with reject tables. The machine is also fitted for gel-filling.

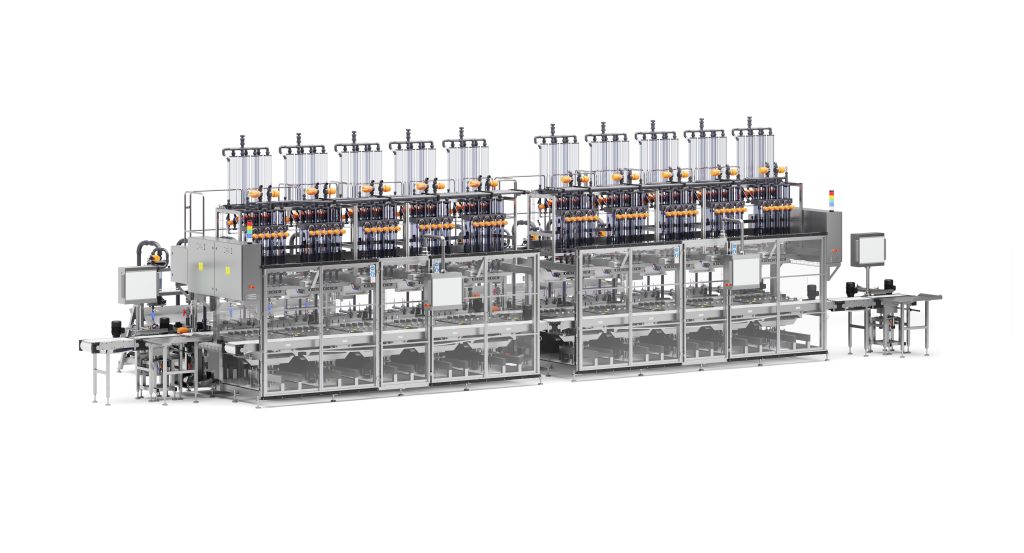

AGM - Ten filling stations

The SF4-8 family is designed for filling VRLA-batteries. The machines are fully automatic filling machines available with different numbers of filling stations, this machine is fitted with fixed filling heads. The filling process is vacuum assisted and uses atmospheric pressure to force the acid into the batteries.

The SF4-8 TEN is the biggest machine we built so far in this family, it features 10 individual filling stations and can process a range of different battery types simultaneously. This machine is designed for filling with cold acid, chilled down to – 20o C, and the acid is measured with an extremely accurate Coriolis mass flow meter. The machine is also fitted with an automatic changing of the filling heads.

SF5 - For 2V batteries/cells

SF5-61 - Six filling nozzles

SF5-61 is a semi-automatic machine for filling of 2V AGM/Gel batteries/cells with a specific acid/electrolyte volume or mass in each cell.

For filling 2V batteries six filling nozzles with hoses will be used. These filling nozzles/hoses can be connected and disconnected to the machine by quick couplings. The machine can fill either 1-6 x2V batteries.

The filling is made by vacuum and the volume is measured by a electromagnetic flow meter or the mass by a Coriolis mass flow meter.

SF4-8 Syringe - For motorcycle and small engines batteries

SF4-8D Syringe

The SF4-8 family is designed for filling VRLA-batteries. The machines are fully automatic filling machines available with different numbers of filling stations, these machines are fitted with fixed filling heads. The filling process is vacuum assisted and uses atmospheric pressure to force the acid into the batteries.

The SF4-8 Syringe is a double machine and has consequently two filling stations. This machine can be designed for filling with cold acid, chilled down to – 20o C, and the acid is measured with a syringe wich gives it an extremely high accuracy for small quanities wich makes it perfect for smaller batteries like for motorcycles and different small engine batteries.

The machine can be custom built in several ways, e.g. for filling of two batteries per filling station and operate with moveable fixed filling heads and so on.

The machine in the picture has options fitted: scale units with reject tables, tank draining unit and a heat exchanger unit.

NiMH-batteries

NiMH (Nickel Metal Hydride) batteries is a rechargeable type of battery. They are used in some hybrid vehicles but otherwise mainly in powerful stationary energy storage solution for home, business or infrastructure where they provide stable and reliable back-up and/or off-grid power supply. The environmentally advantage over lithium batteries is amongst other that the hydride batteries are fully recyclable.

KOH-filler

Instead of acid the electrolyte for NiMH-batteries is an alkaline electrolyte, usually Potassium Hydroxide (also known as lye or KOH). Our KOH electrolyte filler (LF4-8) for bi-polar NiMH-battery modules is fully automatic. It features an integrated vaccum test, high precision filling by a servo assisted syringe unit and an exact control of the cells fill weight. The machine is equipped with scale units, bar code readers and reject stations.

Features

- Filling of NiMH batteries

- Volumetric filling

- 1 or 2 filling heads (LF4-8)

- Capacity is cell dependent

Extendable

The KOH-filler come in different sizes just like our other machines and can be designed to handle retrofitting extra stations later on. The perfect way to grow as your production does. It is also possible to have larger machines with more filling stations than the current single or double.

Filling equipment for NiCD and NiMH batteries

LF4-8 KOH-filler

LF4-8 is a fully automatic KOH electrolyte filler for bi-polar Nickel Metal Hydride (NiMH) battery modules, with integreted vaccum test, high precision filling by a servo assisted syringe unit and an exact control of the cells fill weight. The machine is equipped with scale units, bar code readers, reject stations as well as in- and outgoing conveyors.

The LF4-8 is available as one station or two station filler.

Options

Acid circulation

For filling with cold acid: Acid circulation system to external cooling tank.

Agitator for tank

For Gel fillers an agitator in the supply tank keeps the acid solution in motion and keeping the silica from forming build-ups.

Automatic height adjustment

Automatic height adjustment of the filling heads will reduce time for adjustment and decrease change over time and reduce the risk for incorrect adjustments.

Cabinet Cooler

For cooling of the electrical cabinet, to keep the temperature inside the electrical cabinet from climbing in hot ambient temperature.

Database

We can provide a SQL-database or communicate with an external database. This is used together with scale units to keep track of the individual batteries filling.

Density measuring in tank

When You want or need an exact control of the acid density a density measuring in the tank is possible.

Heat Exchanger

When temperature controlled acid is desired we have the option to fit a heat exchanger onto the machine. The machines are able to handle several minus degrees Celsius.

ICV – Individual Cell Vacuum Monitoring System

For those who require an even higher controlled process we can add the Individual Cell Vacuum Monitoring System. It provides a useful diagnostics on what is happening within each separate cell during filling.

Insulated acid tank

An insulated acid tank is available when using cool acid. The tank can handle as cool acid as down to -40.

Lift Gate Conveyor

A Lift Gate Conveyor is a customized conveyor that makes it possible to open, fold up the conveyor and pass through.

Matrix/barcode printer

We can provide a laser-printer to mark up the individual batteries for the Matrix/barcode readers that work together with a database to keep track of individual filling.

Matrix/barcode reader

When using a Database the reader provides the information for the SQL-database to keep track on every individual filling of batteries/cells.

Nozzle Cleaning Kit

A built-in Nozzle Cleaning System can, based on need, clean the nozzles via a short burst of compressed air to get rid of unwanted particles (often plastic from production). Otherwise filling nozzles may have to be dismounted and rinsed by hand, which leads to unwanted down-time in the production.

Nozzle Template

The use of a template to position the filling nozzles according to recipe/ battery type is highly recommended. A manual positioning is of course possible, but takes significantly longer time. By using a template, the same and correct positions of the filling nozzles is quickly acquired every time, which is very helpful when changing battery types in the filling.

OCV – Open Circuit Voltage test

The OCV is an option for our SK4-1 Acid level control machine, during level control the OCV simultaneously take measures on the battery poles for voltage testing.

Reject unit

A battery reject station is used for rejecting incorrectly filled or faulty batteries in the finishing line.

Remote control

An ability to remotely control the machine is possible for Service or Maintenance purposes or for monitoring purposes.

Rinsing system

A built-in Rinsing system consisting of pipes and nozzles rinses off the filling stations in the machine literally at the push of a button.

Scale units

A set of Scale units will keep track on the battery weights throughout the process. Together with Barcode/Matrix readers and an SQL-database they make a powerful combination.

Tank draining unit

The tank draining system contains a diaphragm pump and is used to effortlessly evacuating the acid from the tank when changing acid density or if the tank needs emptying in relation to maintenance.

Tank with sections

A supply tank for more than one acid density. If you want to be able to work with different acid densities this can be arranged with a tank designed to handle up to three different densities. It reduces down time for draining the tank and filling up with another density.